Click

for Site Directory

Click

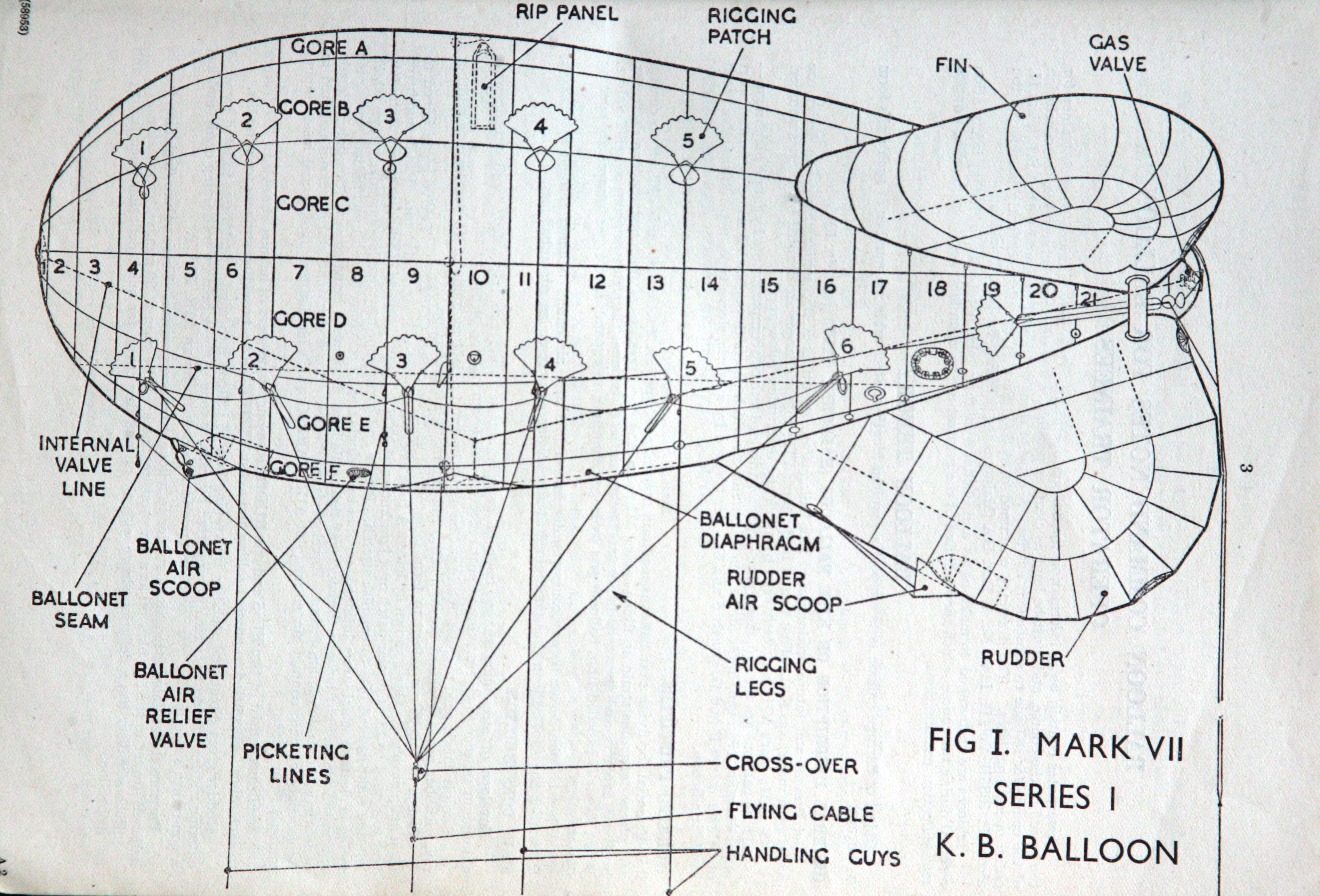

for Site DirectoryThe MK VII Series I Kite Balloon - Its construction and make up.

As can be seen from the above diagram each balloon was made up of a series of panels, totalling 24 in number from the bow to the stern. However from the top to the bottom of the balloon each panel was called a "Gore" and these were named " A-F " inclusive. Every panel was of an exact size and fabric workers had to sew and glue the seams together to construct the balloon. This was a process that meant inhaling considerable fumes form the benzene solvents of the day. As a consolation they were given despite rationing and on medical advice an extra pint of milk a day to cushion the digestive system for this chemical onslaught, history does not record if this ever prevented later life damage to the bodies of these individuals.

The lower third of the balloon was not filled with hydrogen but was called a "ballonet" and was filled with air from a scoop on the underside near to the bow. Between the upper compartment and the lower was a sheet of balloon fabric and the principle was adopted such that as the balloon rose into the air the hydrogen gas would expand and in order to prevent bursting the balloon the lower diaphragm would be forced down into the ballonet which was vented to the air and in this way the balloon did not appear to change shape as the balloon expanded into the ballonet and this change was not normally visible. The wind forced into the forward scoop enabled the ballonet to remain open and capable of taking the extra volume from the top part of the balloon.

At the rear of the balloon were two fins and a rudder, these were filled with air from the scoops and when inflated maintained the balloon head into the wind. This gave stability to the balloon.

At the join of gores B and C were 5 rigging patches used to attach picketing lines, that were in turn attached to handling guys, to to enable the balloon to be handled on the ground. When bedded down the picketing lines were either securely fastened to large concrete blocks in a diamond shape of the picketing lines would be attached to screw pickets, that were like huge corkscrews twisted into the ground.

Between gores D and E were 6 similar patches used for the rigging legs and these were known as "Ton patches " as they were supposed to withstand a weight on them of one ton.

Each of the "Ton patches " were positioned at a precise point along the length of the balloon and each of the rigging legs that came with these was of a precise length. This enabled the 6 cables to meet at a precise point under the balloon and meant that the force of the balloon upward was distributed in a specific way along the cables as they meet at one specific point known as the crossover. In practice this meant that the balloon flew at a slight incline to the ground nose down. After the crossover the flying cable was connected and this the led to the winch.

If the air pressure in the ballonet exceeded a specific level, for instance in a high wind, there was a pressure relief valve in the ballonet that helped keep the pressure within set limits.

Partly on gore A and mostly gore B at panel 10 was special panel called the "rip panel" this panel was designed so that it was securely glued down onto the fabric and underneath it was a hole in the balloon. Between the balloon and the panel was a strand of very sharp cheese wire that was attached to a cord coloured red. It was like an emergency communication cord, pulling it caused the wire to slice through the rip panel exposing the rip panel hole in the balloon and venting the hydrogen to the atmosphere. So in an emergency the rip panel could be activated and the balloon deflated and prevented from running amok. Crews were reluctant to use this unless they had to as refilling it with hydrogen and repairing the panel cost in those days some £500 a time. So it was often only on orders from a senior officer or genuine dire risk of loss of life or loss of the balloon to the elements that the balloon rip panel would be used. In any event such use was always accompanied by an official hearing to justify the cost and exonerate those involved.